Last time, I took a look at the wide variety and history of welding types, from forge welding to robotic welding. Today, I get to the part of welding that was most of interest to those in the gas world, shielding or shield gas.

So, what is a shield gas and what effect might the choice of shield gas have on the weld?

Shielding gases are usually blends of inert or semi-inert gases,  and they are most commonly associated with gas metal arc welding and gas tungsten arc welding (more popularly known as MIG and TIG). Both helium and argon are used in welding. The other noble gases are cost prohibitive. In addition to these noble gases, the semi-inert carbon dioxide, oxygen, nitrogen, and hydrogen are used. The first gases used in welding were helium and carbon dioxide back in World War II.

and they are most commonly associated with gas metal arc welding and gas tungsten arc welding (more popularly known as MIG and TIG). Both helium and argon are used in welding. The other noble gases are cost prohibitive. In addition to these noble gases, the semi-inert carbon dioxide, oxygen, nitrogen, and hydrogen are used. The first gases used in welding were helium and carbon dioxide back in World War II.

When using these gases, it is common to see a blended shield gas mix versus a pure gas. Many resources are available that discuss the commonly used blends, the ratios of each gas in the blend and the pros and cons of each in terms of the resulting weld. By varying the blend or the ratios of gases in the blend, the welder can find the blend that gives the highest quality with the most cost effective shield gas. A few of the more common blends are:

- Argon-Carbon Dioxide

- Argon-Oxygen

- Argon-Helium

- Argon-Hydrogen

- Trimix (Argon-Helium-Carbon Dioxide)

With the multiple gases available and the nearly infinite number of blends you could create, how does the welder decide on the shielding gas or shielding gas blend and what effect does this have on the weld?

The properties that are most critical when selecting shielding gas are:

- Thermal conductivity – How does the shield gas transfer heat to the weld around the arc.

- Density – If the shield gas is lighter than air (such as helium), a higher rate of flow is required than if it is heavier than air (like argon).

- Ionizability – The gas influences how easily the arc starts. The required voltage is also determined by the ionizability of the gas. Helium has a high ionizing potential, meaning it can absorb a great deal of energy before becoming ionnized.

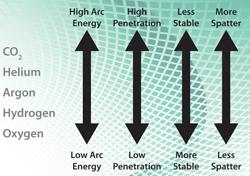

By combining gases to create a shield gas blend, the welder can take advantage of the best qualities of each gas while minimizing the effect of the negative qualities. The image below shows some of the properties of the most commonly used gases. Depending on the materials being joined, the precise blend of gases should allow a safe environment while allowing consistent penetration of the weld. For an interesting article from The Fabricator looking at the need to reevaluate shield gas usage, click here.

|

| The Fabricator, Rethinking weld shielding gas selection, By Dan Davis, Nathan Moyer |

Finally, the shield gases can be purchased as a gas blend or blended onsite from single gas tanks. Often, the cost of pre-blended gas tanks is much higher, and welders find that purchasing a gas blender and delivery system, which can use 100% pure bulk gases, pays for itself and allows a higher level of control of the shield gas mix.

Proper knowledge of the options when it comes to shielding gas selection, generation and useage allows the welder to maintain a consistently high standard while keeping an eye on the bottom line.